Quality Policy

Various tests are conducted in Al Asad Laboratories to ensure that the products comply with quality standards:

- RAW MATERIAL TEST

- Gelation Time

- Bulk Density

- Sieve analysis

- Heat Stability

- FINAL PRODUCT TEST

- Pressure test (§)

- Impact Test (*)

- Chemical Resistance Test (Sulphuric Acid)

- Heat Reversion Test (Shrinkage)

- Water Absorption Test

- Resistance to environmental conditions

- (Extrusion) Methylene chloride test

- Tensile Strength test

- Elongation at break test

- HDT / VSP / Vcat test

- Opacity Test

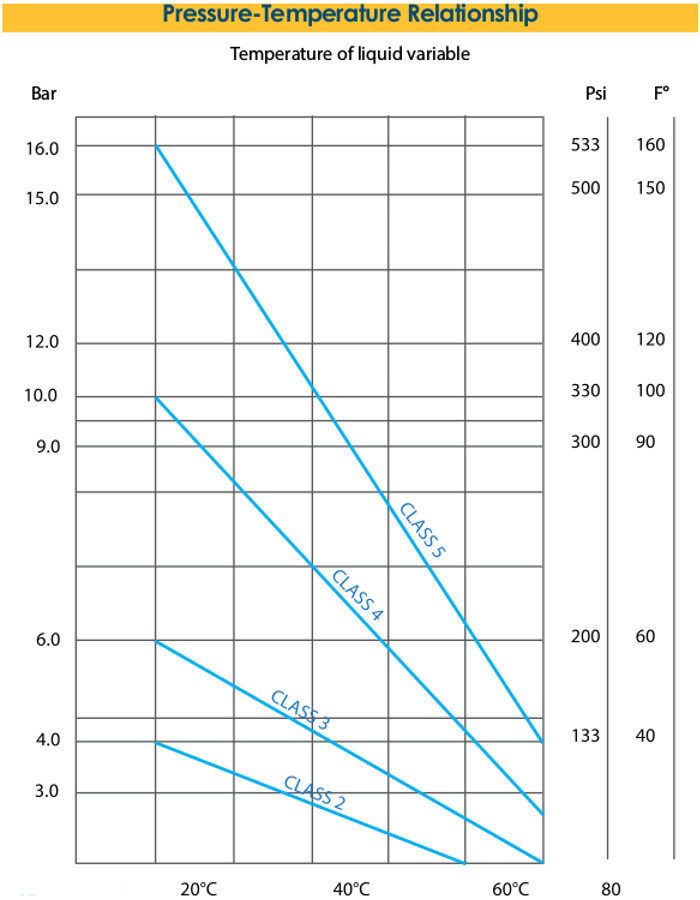

Pressure tests are conducted to ensure that pipes are manufactured in accordance with Saudi standards (14/151996 and 675/1997), German Standard 8061, and American Standard ASTM D1785. The pressure applied varies depending on the size and intended use of the pipes.

An impact test involves subjecting pipes to a striker’s weight, which is increased proportionately to the pipe’s diameter.

Lab Testing Facilities

Al Asad Factory for PVC Pipe and Fittings is equipped with state-of-the-art laboratory equipment, operated by well-qualified engineers. We prioritize high quality and an advanced product range, ensuring we supply only superior quality products to satisfy both domestic and international customers.

We test our materials and products in accordance with various national and international standards.

| Name of the test | Test Method | Value | Unit |

|---|---|---|---|

| Stress Test | SASO 15/1998 | No Balloon, No Burst, No Weep @20°C for 1 Hour and @60°C for 1000 Hours | - |

| Impact Test | SASO 15/1998 | No Crack, No Split | - |

| Opacity Test | SASO 1177/1997 | <0.2 | % |

| Extrusion Test (Methyl Chloride) | SASO 15/1998 | No Attack (20 min) | - |

| Heat Reversion | SASO 15/1998 | No Delamination, No Crack, No Blister | - |

| Water Absorption | SASO 1179/1997 | <40 | g/m2 |

| Sulphuric Acid Resistance | SASO 15/1998 | 0.316 (Increases) @ 55°C 0.013 (Decreases) @ 55°C | g/14 days |

| Toxic Matters Test | SASO 15/1998 | Pb (1st Extraction) <1 Pb (3rd Extraction) <0.3 Sn (3rd Extraction) <0.02 Ba,Cd,Zn (3rd Extraction) <0.01 | Mg/ltr |

| Density | ASTMD-792 | 1.40 - 1.50 | g/cm3 |

| Tensile Strength | ASTMD-638 | 7500 | psi |

| Hardness | ASTMD-2240 | 80±3 | shore "D" |

| Vicat Safening Point | ASTMD-1525 | >80@5 Kgf | °C |

| Heat Deflection | ASTMD-648 | 78@264psi | °C |

Technical Standards Reference

- SASO – Saudi Arabian Standards Organization

SASO 14 Pipes for Potable Water of Unplasticized Plastic (uPVC)

SASO 15 Method of Testing of Pipes for Potable Water of Unplasticized Plastic (uPVC)

DIN-8061 & 8062 German Standards - ASTM – American Standards for Testing and Materials

ASTM D 256 Impact Resistance of Plastics and Electrical Insulating Materials

ASTM Standards ASTM D-1785 for Schedules 40 & 80

ASTM D2241 (SDRS), ASTM F 441. - UL – Underwriters Laboratories Inc

UL 651 Schedule 40 and 80 PVC Conduits

NEMA TC-2, TC-6 AND TC-8

Electrical Plastic Tubing (EPT) and Conduit (EPC-40 AND EPC-80)